Manufacturing Module Guide

Overview

The Manufacturing module in Storemate is designed to convert raw materials into final products. This guide will cover the complete manufacturing process, including adding recipes, managing production, tracking costs, and more.

Options in the Manufacturing Module

- Recipe Management: Manage the exact quantities of raw materials needed to produce the final product using standard instructions.

- Production Management: Manage the total quantity of raw materials required for manufacturing specific quantities of products based on the recipe.

- Settings and Reports: Configure options and access detailed reports, including production costs and stock reports.

How to Work

- Enable Module: Update your subscription for the Shopify Module. (Contact Storemate Support)

- Add Recipe: Follow the steps below to add a new recipe.

Adding a Recipe

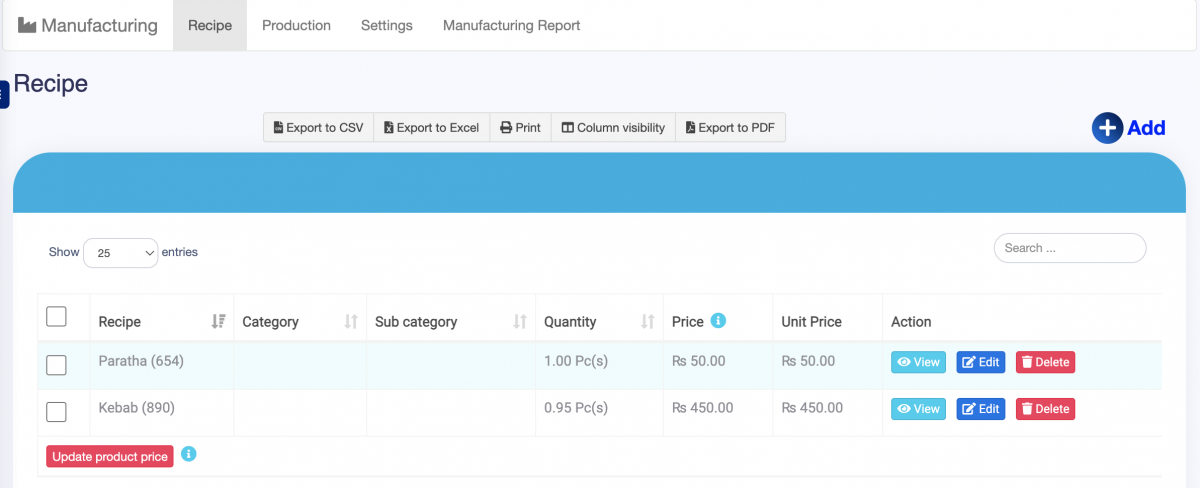

- Navigate to Manufacturing → Recipe.

- Click on Add to open the recipe form.

- Select the product you want to add a recipe for and optionally copy from an existing recipe.

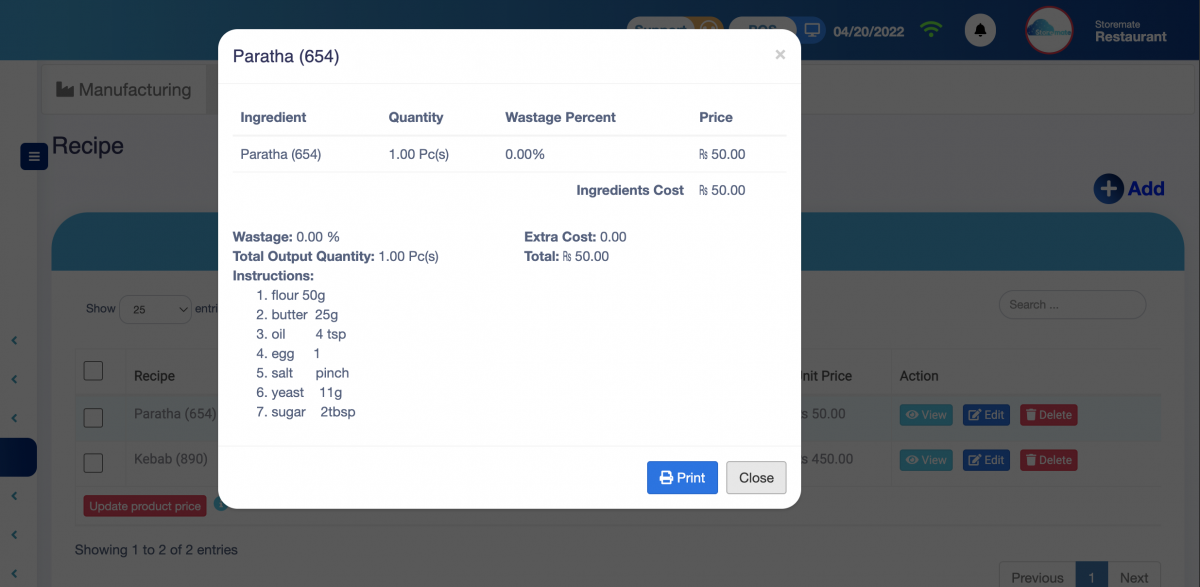

- Add all ingredients, specify wastage percentage, and final output quantity.

- Raw Ingredients: Choose from the product list. Mark them as “Not For Sale” if needed.

- Wastage %: Specify wastage for raw ingredients.

- Total Output Quantity: Output quantity for the recipe.

- Recipe Instructions: Define the steps to convert raw materials to the final product.

Add Production

- Go to Manufacturing → Add Production.

- Select the business location and the product for manufacturing.

- Specify the final quantity to manufacture, including wastage percentage.

- Finalize the production by checking the checkbox, which will adjust the stock levels.

Settings

Configure production preferences, including:

- Production Ref No. Prefix: Prefix for auto-generated production reference numbers.

- Disable Editing Ingredients Quantity: Prevent changes to ingredient quantities during production.